Exploring the Excellence of Titanium Screw Manufacturing

When it comes to the construction industry, choosing the right materials can mean the difference between success and failure. In this highly competitive field, the role of a titanium screw manufacturer is not only vital but paramount. With the increasing demand for sustainable and long-lasting materials, titanium screws have emerged as a game changer. This article will delve into the significant aspects of titanium screw manufacturing, why these products stand out, and how they cater to the needs of general contractors worldwide.

What Makes Titanium Screws the Preferred Choice?

Titanium screws possess an array of outstanding properties that make them highly sought after in various industries. Below are some of the key benefits:

- Lightweight: Titanium is approximately 45% lighter than steel, making it an ideal choice for projects where weight is a critical factor.

- Corrosion Resistance: Naturally resistant to corrosion, titanium screws are perfect for harsh environments, including marine and chemical applications.

- Strength-to-Weight Ratio: Titanium possesses an exceptional strength-to-weight ratio, providing durability without compromising on weight.

- Biocompatibility: In sectors like medical device manufacturing, titanium’s biocompatibility makes it a safe choice for implants and other applications.

- High Operating Temperatures: Titanium can withstand high temperatures, making it suitable for applications in engines and turbines.

The Process of Titanium Screw Manufacturing

The journey of steel and titanium from raw materials to finished screws is an intricate process that involves several stages. For a titanium screw manufacturer, the primary steps include:

Raw Material Selection

The first step involves choosing high-grade titanium alloys. The most common titanium alloys used in screw manufacturing are Ti-6Al-4V and CP titanium, known for their strength and corrosion resistance.

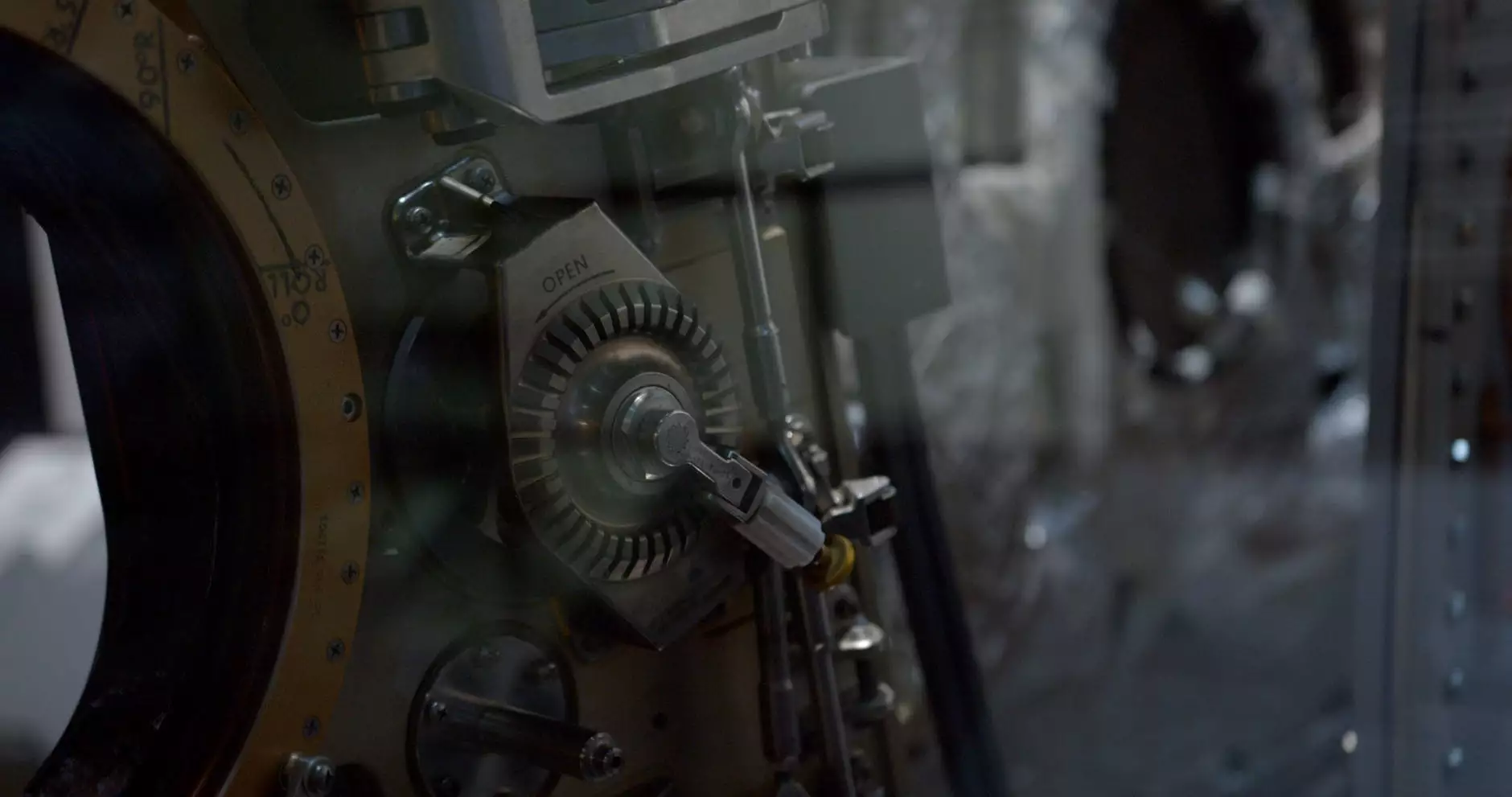

Machining Process

After selecting the raw material, the manufacturing process begins. This involves machining the titanium into precise screw specifications through processes such as:

- CNC Machining: Using computer numerically controlled (CNC) machines to ensure accuracy and consistency in dimensions.

- Thread Cutting: Creating threads on the screws using various techniques like rolling or cutting, which are essential for their functionality.

- Finishing: Applying surface treatments to enhance performance characteristics, such as anodizing or coating.

Quality Control Measures

A reputable titanium screw manufacturer implements stringent quality control measures throughout the manufacturing process. This includes:

- Dimensional Inspection: Ensuring that the screws meet the specified dimensions and tolerances.

- Material Testing: Conducting tests such as tensile strength, hardness tests, and metallurgical analysis to ensure material integrity.

- Performance Testing: Installing screws in a real-world environment to evaluate their performance under various conditions.

Applications of Titanium Screws

Thanks to their unique properties, titanium screws find applications across various sectors. Here are some notable industries:

1. Construction

In the construction sector, titanium screws are prized for their strength and resistance to environmental factors. They are commonly used in:

- Pre-fabricated structures

- High-rise buildings

- Marine constructions

2. Aerospace

In aerospace applications, weight savings are critical, and titanium screws help achieve that without sacrificing performance. They are used in:

- Aircraft frames

- Engine components

- Spacecraft assembly

3. Medical Devices

Due to their biocompatibility, titanium screws are widely used in medical applications such as:

- Implants

- Surgical instruments

- Prosthetic devices

Choosing the Right Titanium Screw Manufacturer

With numerous manufacturers available, selecting the right titanium screw manufacturer can seem daunting. Here are essential factors to consider:

Reputation and Experience

Choose a manufacturer with a proven track record in the industry. Research their reputation through reviews and case studies to gauge their reliability.

Certifications and Compliance

Ensure the manufacturer meets ISO and other relevant industry standards, which guarantees that their products meet quality standards.

Customization Options

Great manufacturers offer customization options to tailor screws to specific needs, ensuring they meet the precise requirements of your project.

Customer Support

Responsive customer support can significantly enhance your buying experience. Ensure the manufacturer provides excellent after-sales support and technical assistance.

Future Trends in Titanium Screw Manufacturing

As industries evolve, so do the demands for advanced manufacturing techniques. Here are some trends shaping the future of titanium screw production:

1. Advanced Manufacturing Techniques

3D printing and additive manufacturing are revolutionizing the production of complex-shaped titanium screws, allowing for greater design flexibility and efficiency.

2. Sustainability Focus

There is a growing emphasis on sustainability in manufacturing. Companies are looking for ways to reduce waste and energy consumption while sourcing materials responsibly.

3. Enhanced Materials

Research into new titanium alloys is ongoing, leading to improved properties such as higher corrosion resistance or better fatigue strength, making screws more resilient in challenging environments.

Conclusion

In conclusion, the role of a titanium screw manufacturer is indispensable in today’s construction and manufacturing landscapes. By choosing titanium screws, general contractors can enhance their projects' durability and performance while also contributing to sustainability efforts. As a leader in the titanium screw manufacturing industry, Titanium Bolts offers superior quality products designed for every application. Knowledge is power—understanding the advantages and processes behind titanium screws can help businesses navigate the complex landscape of high-performance materials.

For more information on high-quality titanium screws and how they can elevate your next project, explore the offerings at titaniumbolts.com.